- Venetian Concrete

- Services-VC

- Case Study – Autostore

FEATURED PROJECT: AUTOSTORE

Autostore Case Study

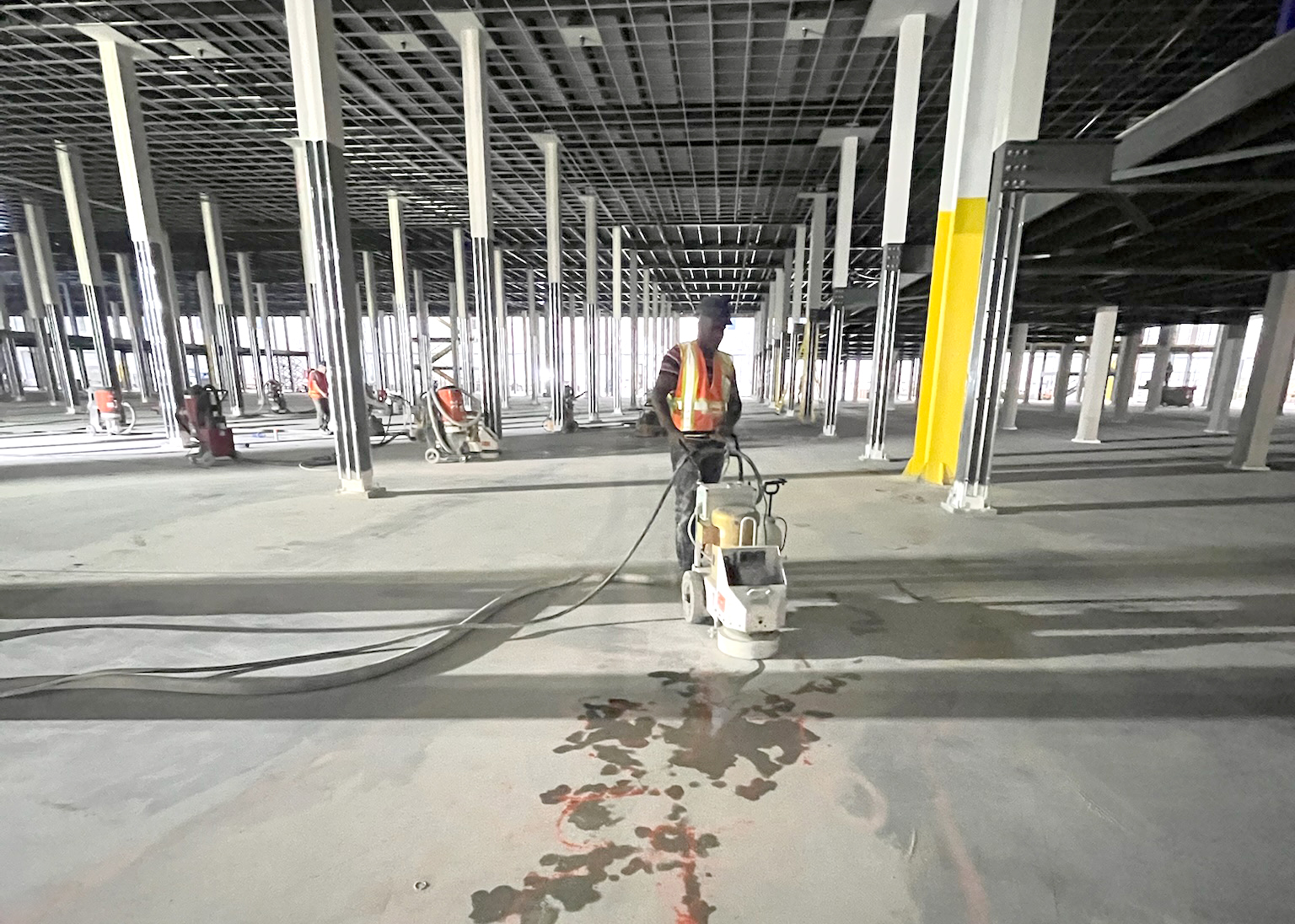

A cutting-edge 120,000 sq. ft. Autostore facility in Brampton, Ontario, one of the largest of its kind in North America, demanded an exceptionally strict floor flatness specification to ensure flawless robotic navigation within its advanced warehousing system.The challenge?

Achieve no more than 6mm of deviation over 2.4 meters, while meeting several other precise flatness tolerances across the entire facility.

How We Delivered:

Our team deployed a full arsenal of specialized, electric, and dust-free equipment, perfectly suited for this mission-critical project:

Single-Head Rotary Grinders:

For pinpoint correction of localized deviations and fine-tuning floor flatness.

Large-Scale Planetary Grinders:

Deliver fast, efficient removal of significant surface irregularities.

Laser-Guided & Manual Milling:

Essential for correcting joint deviations caused by poor pours or settlement. Milling is the most effective technique to quickly and precisely re-level slab joints ahead of final grinding.

Precision You Can Measure:

We eliminate variables by combining laser surveying technology, micrometer depth drilling, and expert craftsmanship, ensuring every slab meets — or exceeds — specification.

Our team integrates seamlessly with your site’s electrical system to power our fully electric equipment, ensuring a clean, dust-free operation.

At Venetian Concrete, nothing is left to chance — only flat, flawless results.

-

Client:

Confidential

-

Category:

Measurement & Reporting, Levelling, Flattening.

-

Date:

2025

-

Contact Information

VENETIAN CONCRETE

9 Nixon Rd, Unit #2

Bolton, ON

L7E 1G5

Links to More Information

© All Copyright 2025 by Venetian Concrete Inc. Site Designed by Product Pixel D&B.